Humiscope Design and Build an Ultra Dry Room for Global Supercapacitor Manufacturer

pUBLICLY LISTED COMPANY, Cap-xx REQUIRED ULTRA DRY ROOM EXPERTS TO EXPAND THEIR GLOBAL PRODUCTION LINE

INTRODUCTING Cap-XX

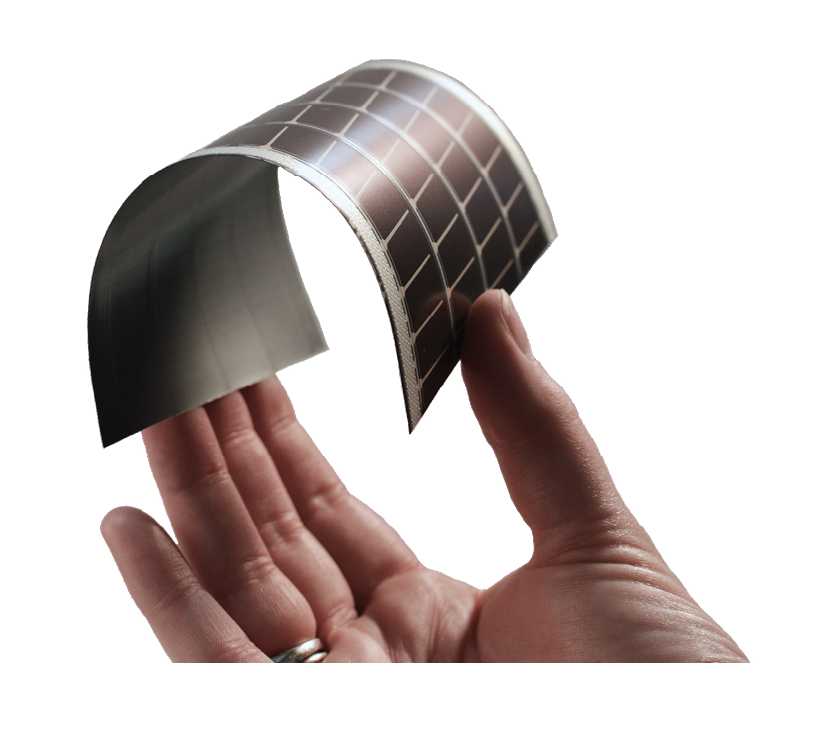

Backed by some of the world’s leading technology investors and listed on the London Stock Exchange, Australian corporation CAP-XX, is a world leader in the design and manufacture of thin, flat supercapacitors

Cap-XX develops, manufactures, and sells supercapacitors to the Asia Pacific, European and North American markets.

Supercapacitors are energy storage devices that offer what is missing between batteries and conventional capacitors. They store more energy than capacitors and supply it at higher power than batteries.

The unique feature of Cap-XX supercapacitors is that it offers very high-power density, ultra-long life and high energy storage capacity in a space-efficient prismatic package.

THE CHALLENGE

CONSISTENT CONDITIONS REQUIRED

In late 2019 Cap-XX acquired its Japanese branch, Murata. In 2020 it relocated the Murata supercapacitor production line to its Sydney Manufacturing plant.

As a result, Cap-XX needed to expand its Sydney facility and add an additional production space.

In order to manufacture supercapacitors an ultra-low humidity, low dew point, ultra-dry room is required.

Incorrect conditions can adversely affect the performance of supercapacitors because the structure of nanomaterials can be altered during electrode preparation which may hinder achieving the best electrochemical performance.

“We chose Humiscope because they had a good understanding of our requirements which led to a tailor made option suited to our process and available budget. ”

Humiscope are experts in designing and building ultra dry, ultra low humidity, low dew point rooms

A consistently maintained low humidity, low dew point, ultra-dry room is required

ENTER HUMISCOPE

INDOOR ENVIRONMENT SPECIALISTS

“Humiscope offered strong customer service throughout the entire project and backed it up with thorough technical knowledge.”

Humiscope has over 30 years’ experience specialising in indoor climate and air quality control solutions from HVAC+R systems to turnkey climate controlled rooms.

In 2020 Humiscope was contracted by Cap-XX to convert a large warehouse into an ultra-dry production room.

Part of the materials used to make Supercapacitors are hygroscopic powders of activated carbon. The handling of moisture sensitive material in manufacturing requires an ultra-dry environment.

In the meeting with Humiscope, Cap-XX was able to ascertain that Humiscope was highly skilled and understood the specific needs of the industry.

“Humiscope offered strong technical support during the inquiry and tender process which provided confidence in the technical knowledge of the company. ”

THE SOLUTION

WORKING TOGETHER

Humiscope and Cap-XX worked together to ascertain the specific requirements of the space. With the solution being:

An ultra-dry, ultra-low humidity production space. With a dew point of minus 55 and a consistent room temperature of 22° C. Warm but ultra-dry.

Discussion Points:

Cap-XX business requirements

Main concern/issues

Ultra-dry room capacity

Ultra-dry room conditions

Ideal climate

Budget constraints

Working with Humiscope through the design was smooth and Humiscope worked well to overcome technical challenges presented with a space constrained project site.

~ Dallas Garratt, GM Operations - Cap-XX Australia Pty Ltd

Humiscope designed the HVAC system which comprised of a Low Dew Point TFT Desiccant Dehumidifier and Clivet Glycol Chiller - which was set to chill the water system and feed -5° water to the dehumidifiers’ pre-cooling coil.

The dehumidifier worked to cool and dry the air simultaneously.

Humiscope techs and engineers prebuilt the machinery at their workshop, retrofitting the two systems together before transporting it to Cap-XX. Once on site Humiscope installed the equipment by running fully sealed duct between the systems and the room.

“The system is essential for our production process and operates 24/7. It has been very reliable since installation. The room is consistently dry at -50°c to -55°C and quick recovery rate after operator entry”

HUMISCOPE ULTRA DRY ROOM SPECIALISTS

Humiscope specialise in creating the ideal indoor climate. We provide solutions that establish and maintain reliable, safe and effortless operations.

We have over 35 years’ experiences specialising in energy-efficient indoor air quality and climate solutions.

We have worked with a diverse range of industries across a wide range of applications.

Design, build and install turnkey climate controlled rooms

Custom design HVAC+R systems with a focus on dehumidification technology.

Find our more about what is involved in designing and building an ultra dry room for Lithium Battery testing and Manufacture