Precise Humidity Control for Pharmaceutical & Nutraceutical Manufacturing

Prevent product degradation, protect hygroscopic materials and maintain GMP & TGA compliance.

✔ Serving Australian pharmaceutical manufacturers for 30+ years

✔ Custom GMP-ready designs

Precision humidity control is essential for the consistent quality, safety, and shelf life of pharmaceutical and nutraceutical products. From R&D laboratories to mass-production facilities, fluctuations in relative humidity can affect both chemical and mechanical properties compromising the integrity of tablets, capsules, and coatings..

Request a Pharmaceutical Assessment

We respond within 24 hours.

This all-in-one desiccant dehumidifier and air conditioner was installed for a GMP-compliant pharmaceutical facility in NSW. It provides precise temperature and humidity control for production and packaging environments.

““A Huge Thank you for your help today. Andrew got the unit up and operational very quickly. Your assistance was greatly appreciated. ”

Dehumidifiers for Pharmaceutical & Nutraceutical Manufacture

A pharmaceutical-grade dehumidifier system maintains precise low-humidity conditions to protect sensitive materials and prevent moisture-related degradation.

Our systems help you:

Prevent caking, sticking, and powder flow issues

Improve coating consistency and drying performance

Protect hygroscopic compounds

Maintain compliance with TGA & GMP standards

We advise on desiccant vs. refrigerant dehumidifiers based on:

RH requirements

Room classification

Heat load

Airflow and pressure requirements

Integration with existing HVAC

Climate-Controlled Pharmaceutical Production

Humiscope designs and builds controlled temperature (CT) rooms and low-humidity environments for pharmaceutical and nutraceutical manufacturing across Australia.

Our custom solutions integrate HVAC, refrigeration, desiccant or refrigerant dehumidifiers, thermostats, and high-performance insulation to achieve precise temperature and relative humidity control.

Check out our ‘Climate Control Rooms’ for more information

Whether you require a validated cleanroom for capsule drying or a large-scale production space with stable RH levels, Humiscope engineers and technicians deliver systems that meet stringent GMP standards.

Applications of Humidity Control in Pharmaceutical Manufacturing

Gelatin Capsules

Both hard and soft gelatin capsules require strict humidity and temperature regulation during formation and drying.

If humidity is too low, gelatin becomes brittle; too high, and it fails to solidify correctly. Humiscope systems maintain ideal drying conditions, ensuring capsule uniformity and preventing product loss.

Tablet Pan Coating

Moisture during the coating process can alter the stability and release profile of the finished product. Our systems supply dry, temperature-controlled air to coating pans, enabling efficient evaporation and consistent film quality.

Effervescent & Hygroscopic Compounds

Effervescent tablets and hygroscopic powders are extremely moisture-sensitive. Maintaining low RH throughout production and packaging prevents unwanted absorption and preserves reactivity.

Not sure which humidity level your process needs?

→ Talk to an Engineer 1300 686 822

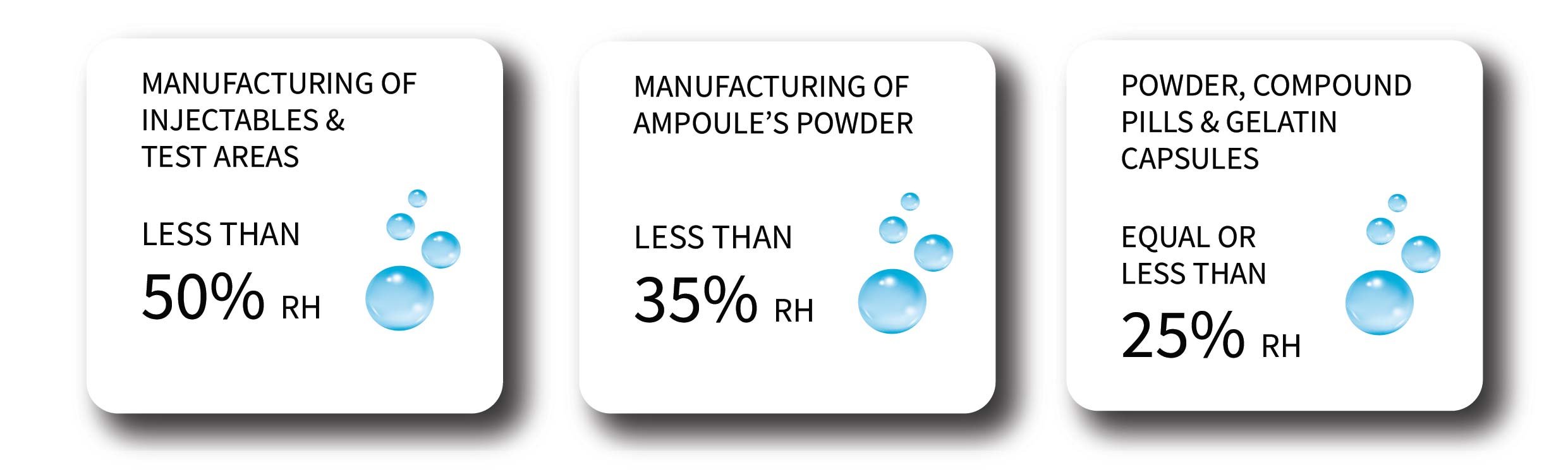

Ideal Humidity Levels for Pharmaceutical Manufacturing

All humidity recommendations align with common GMP AND TGA manufacturing requirements.

For most powder and compound formulations, the relative humidity should not exceed 25% RH. The optimal inlet airflow for coating pans is typically between 32–35 °C with 15–20% RH.

Maintaining these precise conditions reduces batch variation, prevents microbial growth, and ensures compliance with industry standards.

Examples of necessary humidity control in pharmaceutical manufacturing:

Trusted by Australian Manufacturers

“Our manufacturing business has been using Humiscope for several years. They are always responsive & professional. Recently they completed a significant project for us & it was delivered on time & to a very professional standard. I have no hesitation in recommending Humiscope”

Case study of an Australian white label Pharmaceutical Manufacturer who had moisture and humidity related issues within its packaging area and how Humiscope resolved this.

READ THE CASE STUDY

Humiscope offers dehumidifier hire and purchase options across Australia, with engineers and technicians based along the east coast - Queensland, New South Wales, and Victoria.

We also provide maintenance and calibration services for all brands of humidity-control equipment.

AUSTRALIA WIDE SUPPORT

Ready to control humidity in your pharmaceutical facility?

Our engineers design, install, validate, and maintain humidity-controlled environments that meet GMP standards.