Stop Moisture Ruining Your Plastic Production

Reliable Dehumidification for Injection Moulding & Plastics Manufacturing

Moisture in the air can cause havoc in the manufacture of plastics. Reduce rejects, prevent condensation on moulds and keep granules dry with engineered dehumidification systems for plastics plants.

HOW DOES MOISTURE AFFECT PLASTIC?

Moisture in the air condenses on cold moulds and is absorbed by plastic granules. That leads to defects, quality issues and unplanned downtime.

Condensation on moulds creates surface defects and shock cracks

Granules absorb moisture, causing bubbles and voids in finished parts

Stored hygroscopic compounds degrade and change properties

Loss of clarity and poor crystalline structure in clear plastics

Clarity and crystalline structure of end product is of poor quality.

Get tailored advice for your plant

TALK TO AN ENGINEER

We respond to quotes within 24 hours.

Dehumidifiers Designed for Plastics Manufacturing

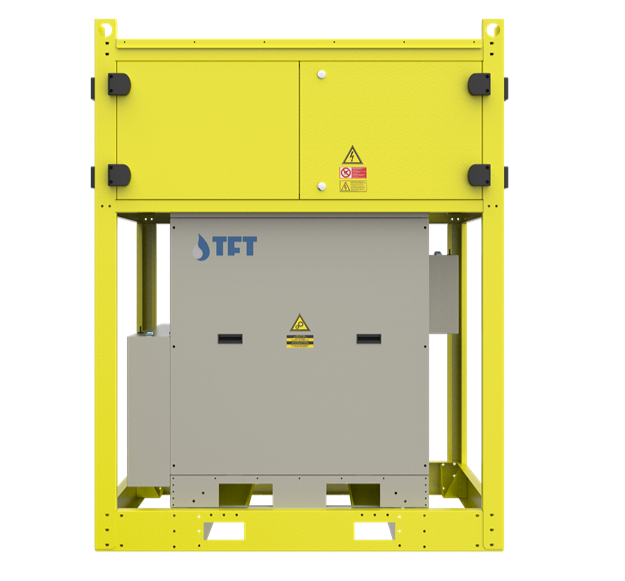

Mould Dehumidification System

Injection Moulding, thermo forming and polymer storage without condensation is possible!

How it works

Keeps the air around the moulds dry at a controlled temperature of 5°C or lower, eliminating condensation on cold surfaces.”

What it does for your line

Eliminates water droplets on moulds

Prevents corrosion and mould growth

Stabilises mould temperature for consistent production

Impact on production

Shorter cycle times

Fewer rejects and quality claims

Less unplanned maintenance on moulds and equipment

Improved Raw Material Storage

Keeps hygroscopic granules dry in silos and bins

Stops moisture uptake before processing

Protects raw material quality between deliveries

Improved Plastic Products

Eliminates shock cracks and moisture defects

Improves clarity and crystalline structure of clear parts

Enhances surface finish by keeping mould surfaces dry

No Effects from Weather or Changing Seasons

System performance unaffected by ambient temperature swings

Maintains stable air conditions year-round

Ensures consistent product quality in summer and winter

Improved Mould Storage

Keeps stored moulds below 50% RH to prevent corrosion

Reduces need for greasing and cleaning before use

Stops condensation in pneumatic systems and sticking granules

Ready to fix moisture problems in your plant?

Plastics Manufacturing Brochure

NO EMAIL REQUIRED

DEHUMIDIFIER HIRE

Not ready to invest? Test the results first.

Rent a desiccant dehumidifier during peak humidity months and measure the impact on cycle times, reject rates and downtime.

Ideal for trials and pilot lines

Seasonal climate fluctuation issues

Fast deployment to existing plants

Option to apply rental costs towards purchase

Visit our Dehumidifier Hire page to learn more - we have seen many industries benefit greatly from the temporary use of dehumidifiers.

FAQ

Here are some of the most common questions we receive from plastics manufacturers looking to improve quality, efficiency, and environmental control in their production space.

-

Moisture in hygroscopic resins can cause defects such as silver streaking, splay, and warping. Controlling humidity ensures resins stay dry before processing, improving surface quality and dimensional accuracy.

-

Yes. Our engineered solutions can be integrated into your current HVAC+R system or installed as standalone desiccant units, depending on your facility layout and production requirements.

-

It depends on your process. Many facilities only require targeted humidity control at the moulding machines or drying area, while high‑precision manufacturing may need a dedicated, climate‑controlled room. We design both.

-

Yes. Lower humidity and low dew point conditions help resin dryers work more efficiently, often reducing drying times and energy consumption.

-

We assess several factors including room size, production heat load, airflow patterns, number of people working in the area, moisture sources, and your required dew point. This ensures we specify a system that maintains stable conditions and delivers consistent performance.

Get in touch

for an obligation free chat about your indoor climate control requirements