Controlled Environment Room Design and Build

Expertly Designed and Built Controlled Environments

With over 35 years of specialised experience in humidity and climate control, Humiscope designs and builds Controlled Environment Rooms (CERs) from the ground up. We also convert existing spaces into fully controlled environments, retrofitting HVAC+R systems and dehumidification technology seamlessly with your existing infrastructure.

Our expertise ensures precise control over temperature, humidity, pressure, and airflow, creating the ideal environment for your manufacturing, research, or storage needs.

“Our manufacturing business has been using Humiscope for several years. They are always responsive & professional. Recently they completed a significant project for us & it was delivered on time & to a very professional standard. I have no hesitation in recommending Humiscope”

What is a Controlled Environment Room (CER)?

A Controlled Environment Room (CER), sometimes referred to as a Controlled Temperature Room (CTR) or Controlled Chamber, is a sealed, insulated space where temperature, humidity, airflow, and pressure are regulated with precision.

While a temperature-controlled room maintains thermal stability, a CER goes further, ensuring consistent, repeatable environmental conditions critical for processes involving sensitive materials, pharmaceutical production, or scientific research.

Industries That Benefit From Controlled Environment Rooms

Humiscope designed dehumidifier used in this controlled environment room - a forensic facility in Brisbane.

Controlled environment rooms are essential for:

Pharmaceutical and nutraceutical manufacturing – ensuring product stability and API quality

Hospitals and laboratories – for research, storage, and testing

Food and beverage facilities – for consistent drying, curing, or packaging

R&D facilities – for replicable test conditions

Industrial applications – where humidity and pressure can affect precision or performance

These spaces provide long-term protection and process control for hygroscopic materials, sensitive compounds, and biological samples.

Controlled Environment Room Design

Every CER Humiscope designs is purpose-built for stability, repeatability, and compliance.

Our engineers use advanced HVAC+R design principles to maintain critical control over:

Temperature and dew point

Airflow uniformity and filtration

Humidity stability

Pressure differential

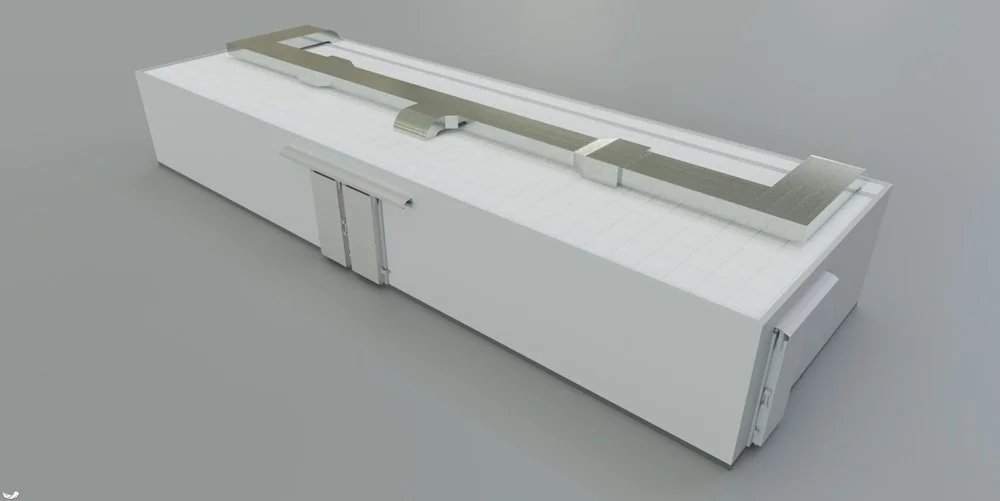

Controlled Environment Room 3d design by Humiscope

We design and install systems capable of maintaining consistent conditions across a wide range of temperature and humidity setpoints.

Designing a CER – Things to Consider

Designing a CER requires careful analysis of:

What is being manufactured or stored

Room size, configuration, and airflow pattern

Occupancy and traffic levels

Material sensitivity to humidity or temperature

Depending on the specific needs, Humiscope integrates high-quality heating, ventilation, refrigeration dehumidifiers, custom thermostats, and heavy-duty insulation to deliver precise indoor climate control.

The Role of Dehumidification in Controlled Environments

One HVAC system we believe is essential within a CER is the desiccant dehumidifier.

Unlike standard refrigerant units, desiccant dehumidifiers remove moisture below the dew point using adsorption technology - enabling ultra-stable, dry conditions ideal for pharmaceutical and industrial environments.

How a Desiccant Dehumidifier Works

Diagram showing desiccant dehumidifier rotor process airflow

Desiccant systems use a rotating silica gel wheel to absorb moisture from process air. Heated reactivation air then releases this moisture, producing a continuous stream of ultra-dry air. This technology ensures:

Greater control over relative humidity

Independence from air temperature and dew point

A dryer, more precise environment year-round

Desiccant Dehumidifiers for Controlled Environment Rooms

Humiscope partners with leading European dehumidifier manufacturers to supply and integrate desiccant systems engineered for pharmaceutical and industrial standards.

Our dehumidifiers deliver:

Fixed airflows and HEPA filtration

Consistent control throughout the Active Pharmaceutical Ingredient (API) cycle

Long-term reliability for R&D, nutraceutical, and manufacturing applications

Humiscope’s team can custom design a dehumidification system to match your controlled environment requirements.

Why Control an Indoor Environment?

A controlled environment ensures that production, storage, and testing take place under consistent and predictable conditions, improving:

Product stability

Process accuracy

Regulatory compliance

Operational efficiency

From pharmaceuticals to precision manufacturing, maintaining the right environment is key to consistent quality.

Contact Humiscope to discuss your Controlled Environment Room design or conversion project.

We provide tailored climate control solutions that help you master your indoor environment.