Humidity in Cold Rooms, Where Does it Come From?

Humidity Issues in Cold Room storage and process freezers

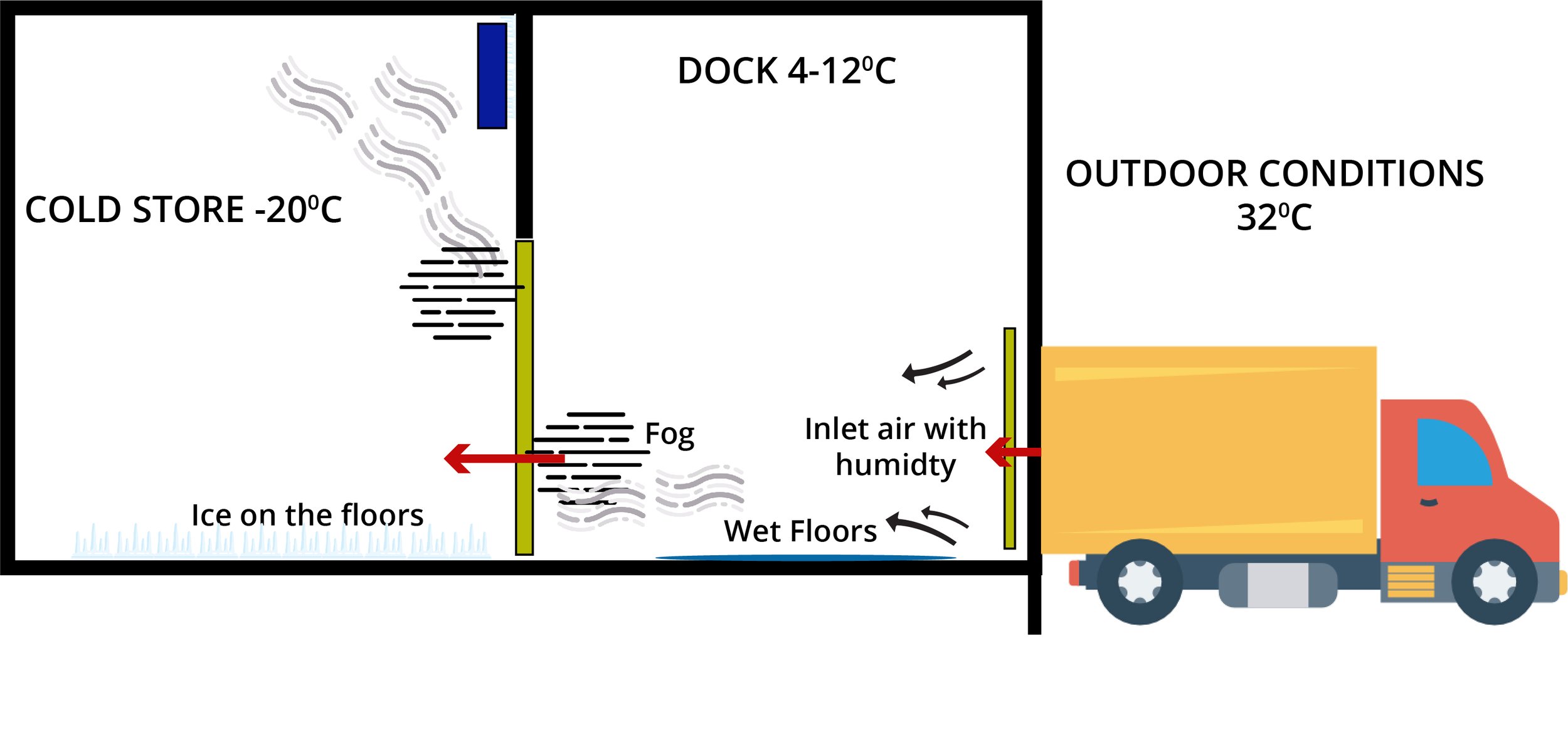

Low temperature cold storage is affected by humidity. Humidity and moisture issues issues lead to:

ice formation around doorways, fans, conveyors and evaporators

low visibility - condensation and fog

safety hazards - slips and falls

critical issues with machinery

doors with damaged seals

broken strip curtains

diminished product quality and loss of stock - damp and damaged packaging

These issues ultimately lead to:

increased operating costs

increased energy consumption

dissatisfied clients/customers.

WHERE DOES THE HUMIDITY COME FROM?

When warmer ambient air is let in, it infiltrates the space. The moisture contained in the warmer air condenses in the form of water or ice.

Although each cold store or freezer is different and rooms can be sealed and equipped with automated doors, infiltration occurs - even through the fastest opening times. If remained undealt with, moisture will build up.

In freezer storage, humidity problems stem from moving goods in and out, causing ingress of moisture-laden air via any opening.

There can be problems with too little air circulation, which can cause pockets of stationary air because the flow of air from the fans cannot reach everywhere within the space.

Find out how a Dehumidifier will help eliminate your humidity issues - eliminating ice build-up, fog and condensation.

Increase product quality and consistence. Reduce production downtime and energy consumption