There are several industries that

manufacture and store hygroscopic compounds and moisture sensitive material where precise moisture and climate control is crucial.

For example, it is vital for a pharmaceutical processing facility to ensure their manufactured medicines and vitamins retain their integrity, from production through to when it leaves the facility.

The integrity can be damaged by even the slightest amount of moisture or the slightest fluctuation in temperature.

How to Master Your Indoor Environment?

Using high quality HVAC+R (heating, ventilation, air conditioning and refrigeration) systems within a specially sealed room is the best way to control your indoor environment. Depending on your specific needs, will determine which HVAC equipment or combination of equipment is required.

Humiscope designs and builds Climate Controlled Rooms

Indoor Environment Specialists

Humiscope design and build rooms from the ground up and also convert existing spaces into controlled temperature rooms. With over 35 years experience in the industry it’s safe to say we know our stuff!

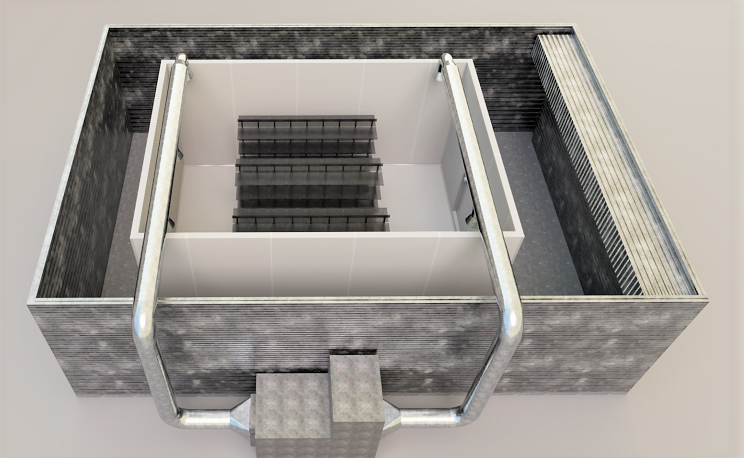

Humiscope draftsman 3D controlled environment room design

A CER is specifically designed and usually built for facilities that require precise temperature management for the production and storage of hygroscopic compounds, tablets and medicines sensitive to moisture and fluctuating temperature.

FIND OUT MORE about Humiscope CER design and build.

Desiccant Dehumidifiers for Controlling Indoor Environments

One HVAC system Humiscope focus on is desiccant dehumidifiers. They are essential within a climate-controlled room.

We work with only the best European industrial and commercial dehumidifier manufactures and can custom design dehumidifiers for temperature controlled rooms that is specific to our clients’ requirements.

Industries that Benefit from Controlled Temperature Rooms

Hospitals, laboratories, and pharmaceutical and nutraceutical manufacturing facilities will house a climate-controlled room or storage chamber to ensure optimal manufacturing processes and the stable storage of medicines, vitamins, and hygroscopic material.

Using a Controlled Environment Room for production and/or storage avoids unwanted moisture, temperature changes and humidity related issues.

For example…

during effervescent tablet manufacture, the relative humidity of the air must be kept at a low level until the product is enclosed in a moisture tight package.

Designed to dissolve in water, any contact with moisture, no matter how minimal, can ruin the entire batch.

A forensic laboratory Humiscope provided with with indoor humidity and temperature control

Temperature and humidity control is crucial for tablet manufacture, storage and transport

Consistently maintained humidity control is crucial when working with hygroscopic compounds