Waste heat recovery is one of those special applications that has been around forever... well nearly forever and yet it's hardly ever considered and is constantly overlooked.

What is waste heat recovery?

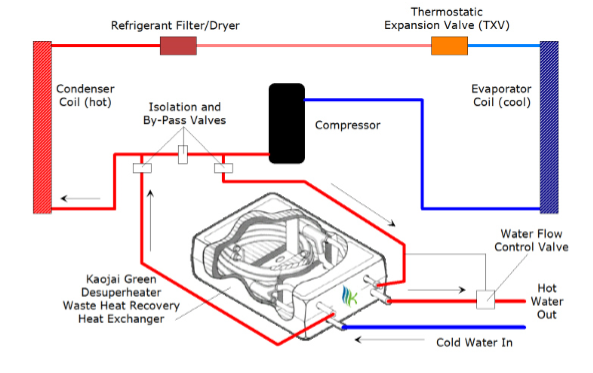

The most widely used form of waste heat recovery is: the process of recovering the waste heat from an air conditioning or refrigeration compressor condenser loop or the hot refrigerant before it goes to the condenser coil.

There are many ways waste heat can be recovered and applied and a Coefficient Of Performance (C.O.P.) of more than 11 to 1 is achievable.

Coefficient Of Performance is the difference between the power input to the usable energy output.

For this article we'll look at a standard air conditioning system where a Coefficient Of Performance of 4.5 to 1 is an easy target to reach.

For the waste heat recovery gurus the advent of the new refrigerants has been a real gold mine... most of the new refrigerants have a higher condensing pressure which also means a higher condensing temperature... more "free heat" for hot water production!

As a basic rule of thumb we can recover about 39% of the total heat of rejection from the compressor. The main reason we don't take more is we only want to reclaim the super-heat, this way we don't start condensing the refrigerant before the condenser.

Total heat of rejection (THR), is the amount of heat being produced by the air conditioning or refrigeration process at the compressors high temperature outlet.

How much hot water can be produced with waste heat recovery?

For this example we'll use an air conditioning system that has 100 kw's total heat of rejection with an estimated compressor run time of 7 hours per day.

Applying our basic principle of 39% that means we have 39 kw's of heat recovery for hot water production. We'll assume a water temperature rise of 30°C ∆T (∆T = temperature difference or temperature rise) through the waste heat recovery heat exchanger: 39 kw x 861 (calculation factor) = 33,579 / 30°C ∆T = 1,119 litres per hour x 7 hours run time = 7,833 litres per day.

The important focus here is this amount of 7,833 litres per day of free heated water just from one air conditioning system.

The return on investment or (ROI) for waste heat recovery retrofits is generally less than one year and I have never seen a return on investment of more than 3 years. The life cycle of the equipment is around 15 years. This represents an incredible and measurable return on investment on the capital expenditure for a waste heat recovery system.

So who can use waste heat recovery?

Pretty much anyone who has an air conditioning or refrigeration (HVAC) system or other heat sources and of course they need to have a requirement for hot water too!

Restaurants

Food manufacturers/processing

Hospitals

Resorts

Pharmaceutical

Laboratories

Microchip processing

Retirement villages

Swimming pools

What are some of the sources of waste heat?

As used in the example in this article, the condenser refrigerant loop is one source and we can also use the cooling tower loop for chilled water HVAC systems, hydraulic oil systems and other fluids that operate at high temperatures. Air compressors and heated exhaust air systems are also a good source of waste heat recovery. Also warm waste process fluids are a excellent heat source.

Waste heat recovery advantage explained.

Waste heat recovery doesn't produce or create hot water it merely transfers existing heat from one source to another. This is energy you've already paid for and by recovering the waste heat you're using the same energy for multiple purposes... maximising your energy efficiency and creating a savings that has a real return on investment.

Waste heat recovery may also improve the performance of the source system. By removing unwanted heat, the condenser becomes more efficient, the cooling tower system is more efficient (as it has less heat to reject) and all of this will reduce energy usage and improve efficiency.

In our next waste heat recovery article we will discuss the waste heat recovery technique from low grade heat sources using a High Lift Heat Pump system with multiple functions of heat recovery and free cooling benefit too!